The Future of Electric Vehicle Motors: YASA’s Axial-Flux Technology

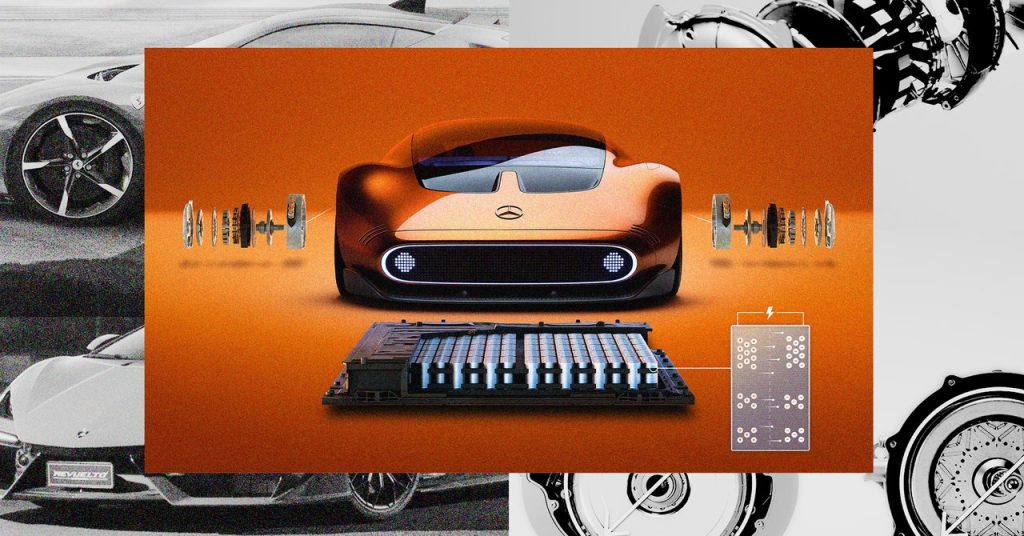

In the world of electric vehicles, the quest for lighter, smaller, and more powerful motors is a constant pursuit. Enter YASA, a British company that has developed a revolutionary axial-flux “pancake” motor design that could transform the architecture and performance of EVs.

Axial-Flux vs. Radial-Flux Motors

Traditional electric motors, known as radial-flux motors, have a cylindrical rotor that passes through and is turned by the magnetic flux flowing radially around the stator’s copper windings. In contrast, YASA’s axial-flux motors feature disc-shaped stators and rotors sitting alongside each other, with the flux flowing axially, parallel to the shaft.

This design offers several advantages, including reduced weight, increased power density, and improved cooling. A YASA motor, similar in diameter to a Tesla motor but one-sixth the length, can deliver 250 horsepower while weighing just 12 kgs—a quarter of the weight and a quarter more power than its Tesla counterpart.

Manufacturing Breakthroughs

YASA founder Tim Woolmer cracked the code for mass-manufacturing axial-flux motors just five weeks into his PhD. His design eliminates the heavy “yoke” found in conventional axial-flux motors, saving around 80 percent of the iron content and making the motor even slimmer and lighter. This innovation also allows for a second rotor on the other side of the stator, further increasing torque.

Cooling and Performance

Woolmer’s unique coil design, which features copper triangular sections wound around soft magnetic composite cores, enables direct oil cooling—something impossible in radial-flux motors. This allows YASA motors to run continuously at 90 percent of their peak power, compared to around 70 percent for radial motors, while maintaining a consistent gap between the stator and rotor despite the immense magnetic forces at play.

Adoption by High-Performance Brands

High-performance brands like Ferrari and Koenigsegg have already embraced YASA’s technology. The Ferrari SF90, the first standard-production car to feature a YASA motor, uses two on the front axle to assist its V12 engine. Koenigsegg’s Gemera hybrid and upcoming fully electric models will also utilize YASA motors.

The Future of YASA and Electric Motors

While some industry experts, such as Lucid Motors‘ VP of powertrain Emad Dlala and Rimac Automobili founder Mate Rimac, believe that radial-flux motors will continue to dominate the mass market due to their scalability and cost-effectiveness, YASA remains focused on pushing the boundaries of axial-flux technology.

“That’s the dream, right? A little Y on the back of an AMG. But we also need to offer a step-change in vehicle architecture, and I hope the rest of the world will fall in with us and Mercedes-Benz as we take this idea into mass production.”

With the backing of Mercedes-Benz, which acquired YASA in 2021, Tim Woolmer and his team are poised to revolutionize the electric vehicle landscape, one pancake motor at a time.

4 Comments

So Mercedes is powering Lamborghini, McLaren, and Ferrari with their EV tech? Talk about an unexpected plot twist!

Mercedes stepping into the EV game and supplying giants like Lamborghini and Ferrari? Now that’s a power move!

Mercedes, now the electric heartbeat of supercar legends like Lamborghini and Ferrari? Bold.

Mercedes really said “move over, I’m the new electric maestro for Lamborghini, McLaren, and Ferrari!”